Overview

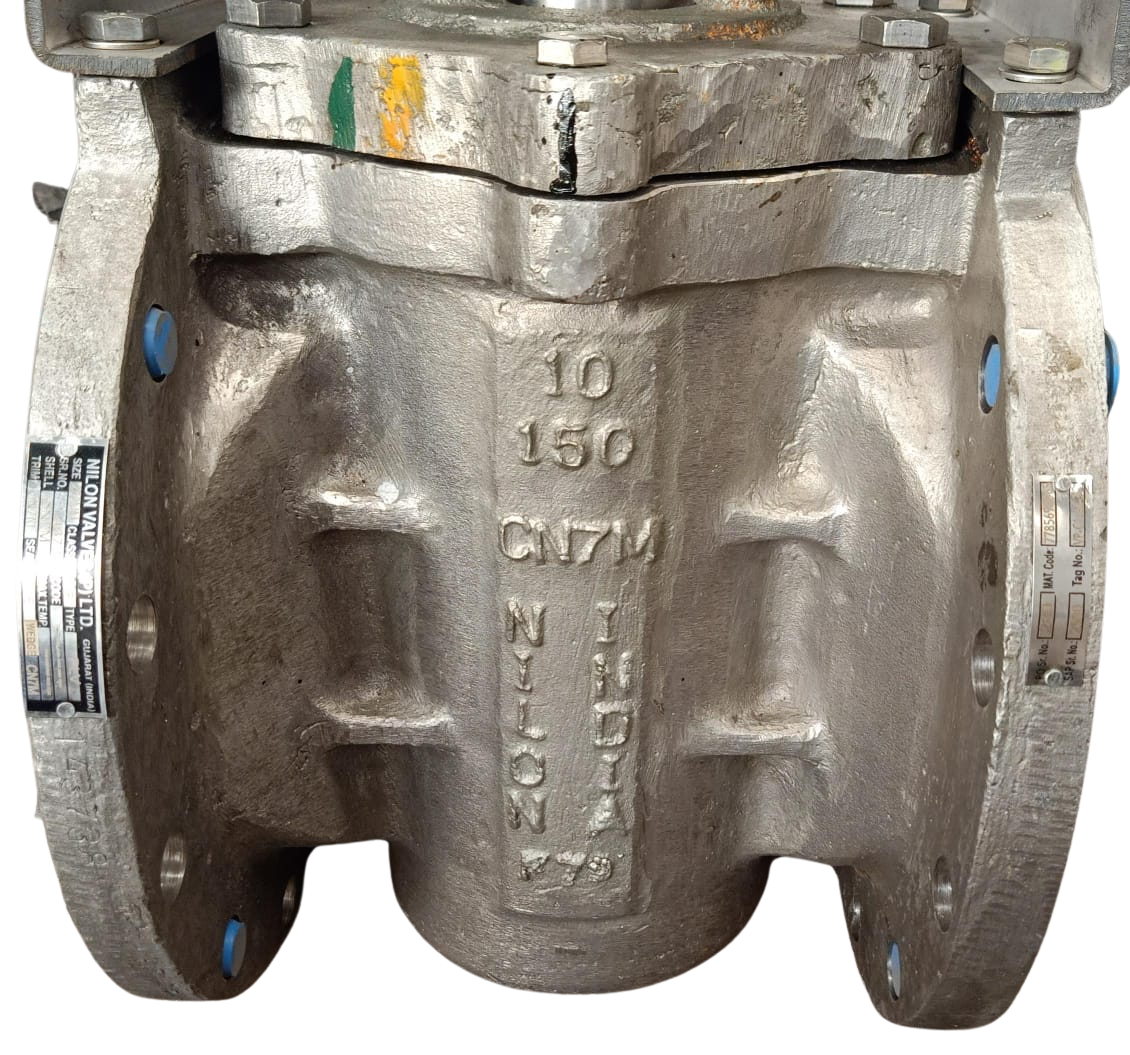

“Nilon” Series Plug valves, also called cock or stop-cock valves, date back to ancient times, where they were developed for use in citywide Roman plumbing systems. Today, they remain one of the most widely used valves for both on/off and throttling services. Their design is fairly simple; the body is comprised of three main parts: body, cover and plug. The plug is a cylindrical, tapered, or generally cone-shaped device that can be raised or lowered within the seat to maintain, restrict or completely shut off flow. The valve is opened by rotation, with the plug itself being the only element that is capable of movement. Early models of plug valves used metal-to-metal seals that were no lubricated. This design is still used, but problems with galling and sticking limit their usefulness. The use of lubricant between the plug face and the seat eliminates most of these problems. The lubricant helps to control leakage around the plug, reduces wear between the valve contact surfaces, and slightly lifts the plug to reduce the operating torque required to operate the valve.

TECHNICAL SPECIFICATION

| Manufacturing Standard | BS 5351 / API 6D |

| Testing Standard | API 598 |

| Pressure Class | 150# to 1500#, PN10 to PN16 |

| Material of Construction Cast |

|

| Design Type | Two Way, Three Way |

| Size Range | ½” Through 18” |

| End Connection | Screwed End, Flanged End, Butt Weld |

| Engineering Options | Manual, Wrenched Operated, Gear Operated, Pneumatic Actuator, Electric Actuator |